FOR IMMEDIATE RELEASE

Contact Ravi Kelkar, Product Manager

EMP Connectors., a Conesys Company

310-222-5780

www.conesys.com

rkelkar@conesys.com

EMP Connectors Invests in Improved Manufacturing and Test Capabilities

(Torrance, CA – October 17, 2012) EMP Connectors, a Conesys Company, has recently invested in improved manufacturing and test capabilities. On the manufacturing side this includes new solder reflow equipment to increase production capacity and improve process control. For test processes, EMP Connectors has added improved automatic testing and data recording capabilities, including automatic Insertion Loss (I/L) measurement, making 100% capture of I/L readings standard on all orders.

Mark Wilkinson, President of Conesys, in announcing the investment said, “At Conesys, we are committed to expanding our EMP Connector Division. This means EMC filtered connectors of many types, as well as transient voltage suppression (TVS) connectors.”

Wilkinson added that designing and manufacturing world class filtered connectors combines both the electronic design and manufacture of the filtering element with the mechanical elements of the connector body and coupling mechanism. These are different disciplines, and many filter connector suppliers specialize in only one or the other. EMP Connectors, he said, “Is a leader in filter design, and now also in filter manufacture and test. But we have the added benefit of being a member of the Conesys family and drawing on our unsurpassed U.S. connector manufacturing facilities.”

EMP Connectors is a division of Conesys, Inc., which also includes Aero-Electric Connector, J-Tech, Inc., Aero Industrial Products and Conesys Europe. For further information, see the Company website at www.conesys.com or email j-tech@conesys.com.

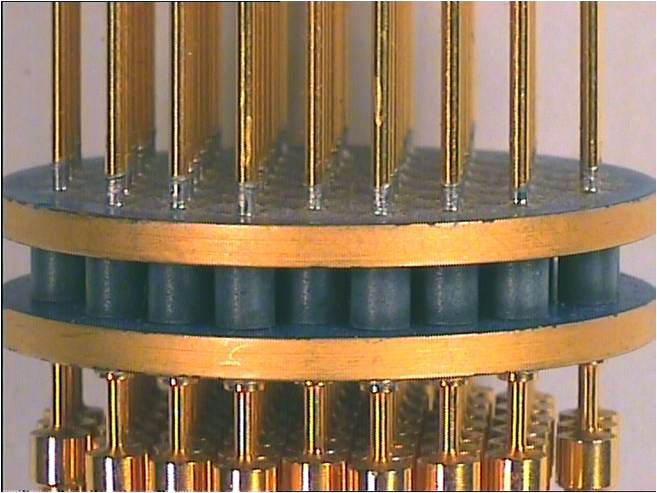

An example of a pi filter assembly built by EMP Connectors for use in a filtered mil/aero circular connector. EMP’s investments will improve manufacturing processes and control, particularly wave soldering, and automate 100% insertion loss testing.

# # #

Aero-Electric Connector – J-Tech – EMP Connector – Aero Industrial Products

Conesys, Inc. 2280 208th Street. Torrance, CA 90501 310-618-3737 Fax: 310-618-3738